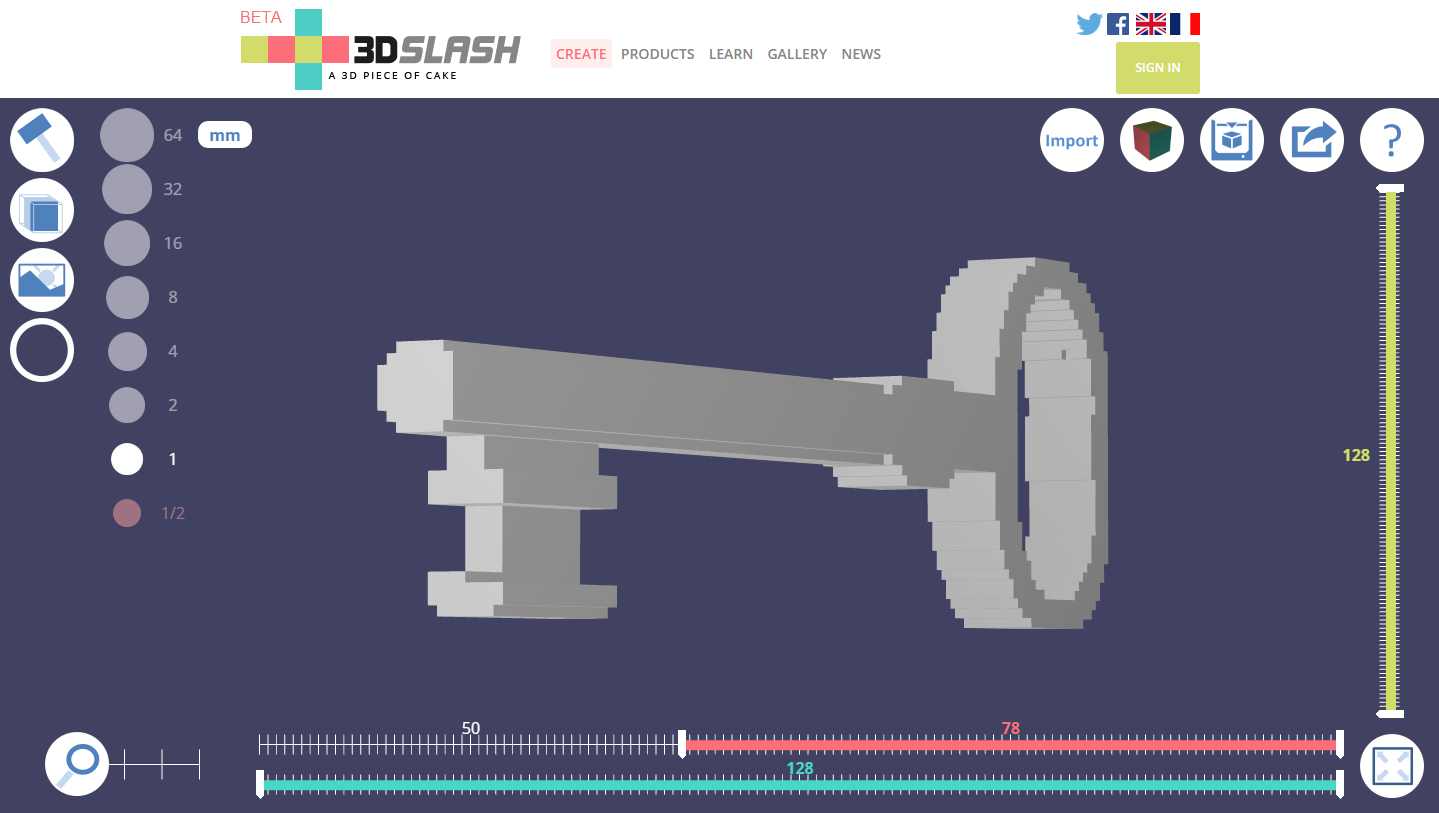

Uniz TechnologyĪ number of objects printed by the Slash SLA 3D printer. "Before Slash, speeds of 1,000 cc/hr were only achievable with large industrial machines that cost over $100,000 now it can be available in your home," Uniz Technology boasts.

The Slash 3D printer uses an LCD light source to harden photosensitive resin a liquid cooling coil below the nonstick surface that separates the printed layer from the bottom of the resin vat keeps it from overheating material during its print cycle.Īs other SLA printers have attempted to improve on print speeds, they have superheated the nonstick layer to 500 to 600 degrees Fahrenheit, damaging the material, according to Houmin. Then, a liquid cooling coil below the nonstick surface that separates the printed layer from the bottom of the resin vat, keeps it from overheating material during its print cycle. Uniz Technology claims it overcame a speed barrier with its Slash SLA 3D printer by using a liquid crystal diode (LCD) to harden the photosensitive resin. Of course, the Carbon3D M1 has a price tag of around $144,000. An industrial SLA 3D printer, such as the Carbon3D M1 machine, can harden up to 60 cc/hr. By comparison, the Form 2 3D printer can use 19 cc/hr.

0 kommentar(er)

0 kommentar(er)